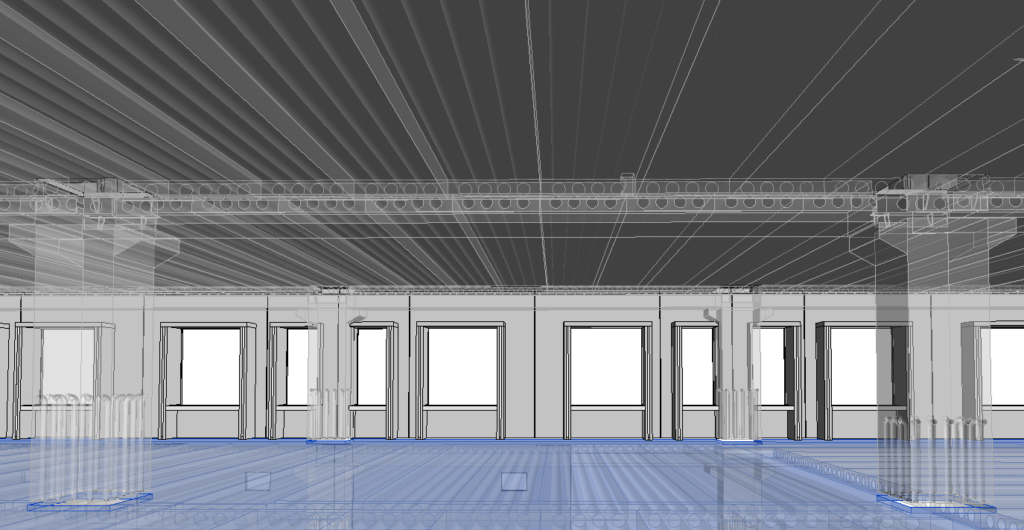

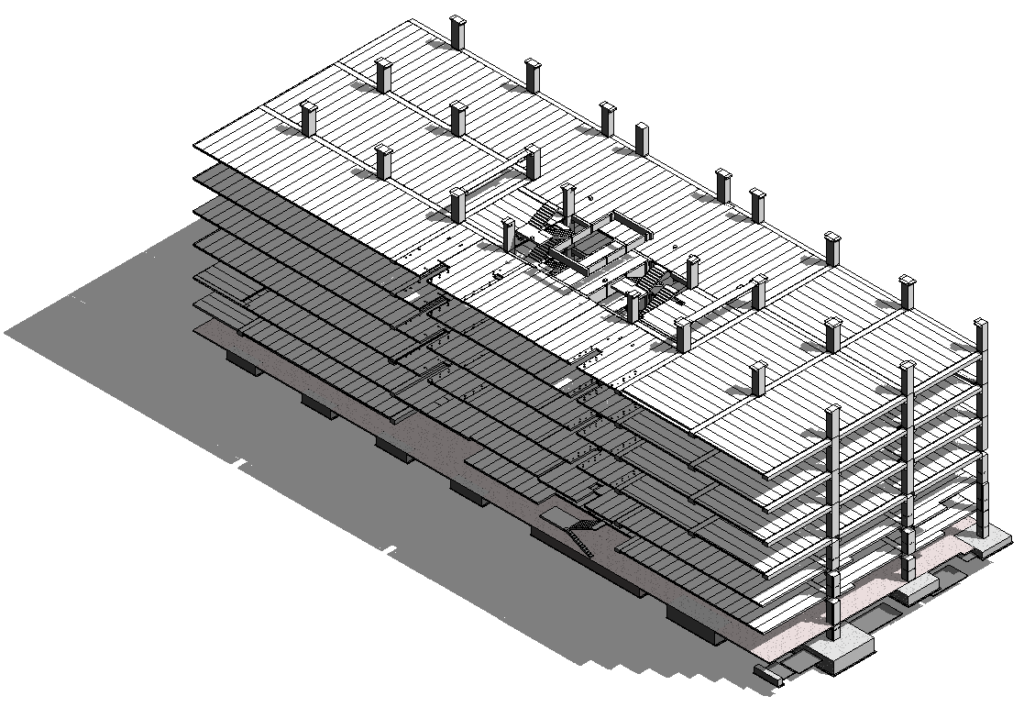

LOD 350 – Precast Structure Model

Client Profile :

The Client is a precast concrete contractor, he is specialised in precast concrete building erection and assembly.

Business Need :

The client is a concrete contractor based in Dubai, they specialize in Precast Concrete and assembly.

- Client wanted to check weight of each precast element, as construction site has certain limitation with respect to lifting equipment’s and access roads.

- Client also wanted, some way to ease out his erection process.

- Client wanted to save money by maximizing moulds for multiple elements.

- Detailed BOQ and Connections details were to be made.

Challenges:

Observation of requirements, workflow, and changes in the given project in the timeline by the project team at BIM Associates, highlights below challenges.

– As the structure was precast, Gaps between structural elements were be precisely maintained in Revit Model also. Rules and very stringent.

– Each Structural element with concrete and rebar should not weight more than 20 tonne.

– The lifting bars should be in proper symmetry, un balance lifting bars may cause damage to structural element or create any accident on site.

– Co ordination with other disciplines added to this challenge.

Solution :

– BIM Team at BIM ASSOCIATES developed a detailed Revit Structural Model with all preset rules for spaces between precast elements.

– All Connections were detailed in 3d model itself. Each structural elements was given unique ID number, which will be later printed on a QR code and will reflect the same on erection floor plan.

– This will made transport, erections smooth.

– All typical set of structural elements were highlighted with client design team, so they can use same mould for casting multiple structural elements and tag them with respect to their unique ID.

– This helped client in saving cost and valuable time in casting and transporting.

– Each element and its weight was checked in Revit and confirmed with client to keep its overall weight under 20 Tonne.

– Full Clash resolution was done with other disciplines.

Approach :

On finalizing the scope and deliverables needed with the client team, below is the flow/approach that our team has used :

- Team with dedicated Project Lead, built a detailed Revit Structural model as per specification and norms given by client design team.

- Each elements was detailed and connections were added to the same in Revit model.

- Once re-baring was done, the weight of the structural elements, clash in any rebar or connection was verified and discussed with client structural design team.

- Once this was done unique ID was given to each structural member, the same ID with be mentioned in erection plan for easy assembly on site.

- Full clash resolution was done with other disciplines, with internal connections so accurate model and bill of quantities can be extracted.

- Typical list of elements were identified and highlighted to client with respect to size and count.

- This help client in overall manufacturing, transport and erection of the building members.

- Also time and material saving was done, which helped in improving overall ROI of the project.

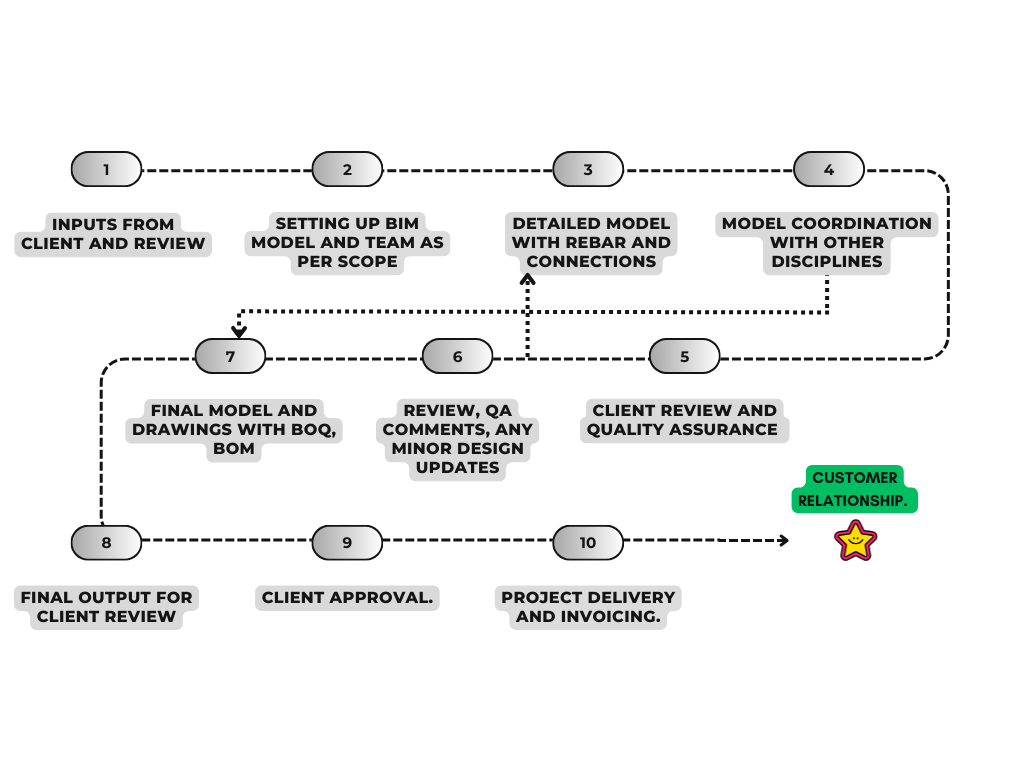

Workflow :

The below is a basic workflow for project. Please note fine details on the same are not shown here.

Software and Technology :

Autodesk Revit, AutoCAD, PyRevit

BUSINESS IMPACT :

– Cost Saving and tight turnaround.

– Core expertise and Pro data Utilization.

– Better Skill and Resource Planning for Business Success.

– Flexible working hours for best project needs.

– Client was able to offer an added package to its end customer, this help our client to expand his business.